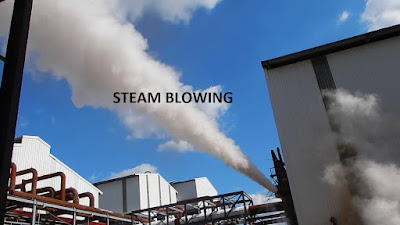

1.What is the purpose of steam blowing?

The purpose of the steam blowing is to remove any foreign materials

from steam piping & super heater coils after completion of erection work.

2.What will happen if steam blowing is not done after erection

or repair of Boiler?

If steam blowing is not done, considerable

damage will happen to the steam lines & other end user applications like

steam turbine, process heat exchangers due to scale, debris & other foreign

materials present in the newly erected pipe lines/coils.

3.What is the basis behind steam blowing?

The basis behind the steam

blowing is to create momentum equal to or preferably greater than that during

normal operation. This will blow out all the debris from the steam lines

4.What are the two different methods of steam

blowing?

Puff method & continuous

method. In puff method thermal shock is created & in continuous steam

blowing, constant steam purge is maintained

5.What are the requirements for steam blowing for

newly erected Boilers?

- Steam blowing area is corned off & notice board or caution board should be displayed

- Ensure Boiler hydraulic test, alkali boil out & passivation procedures are completed before steam blowing

- All the temporary supports used during erection should be removed

- Steam pipe lines & valves used for steam blowing line should be equal to the maximum size of permanent pipe.

- Sharp elbows, bends & tees should be avoided in steam blowing pipe line to avoid more pressure drop

- Temporary pipe lines used for blowing should be well supported to withstand reaction forces created during steam blowing.

- Steam blowing line should be terminated outside the Turbine hall or process

- Sufficient allowance should be given to steam blowing line for thermal expansion

- Ensure steam line supports & hangers are erected & set properly

- Ensure control valves, steam nozzles & NRV flops are not installed during steam blowing

- Initially steam blowing is done at lower mass flow

6.What is the time gap between two steam blows?

For an un insulated steam pipe

line blowing can be done at every 1 hr. And for insulated steam pile line the

gap between two blows should be 3–4 hours

7.Which materials are used for target plates?

Aluminum & stain less steel

8.How do you decide the steam is clear after

blowing?

If there are only two or less than two

recognizable impressions found on per square centimeter of target plate, then

the target plate is said to be clean.

For Target Plate Made of Aluminum:

The piping considered clean if

there are not more than 3 (Three) pitting of 0.5 mm to 1mm dia. in center

area of 25 mm X 25 mm and shall not have any deformed edges. Besides this there

shall be no pitting in the rim zone. Pitting below 0.5 mm may be ignored.

For Target Plate Made of Stainless Steel:

The piping is considered clean if there are not more than five pitting of 0.1 mm dia to 0.5 mm dia. in center area of 50 mm X 50 mm & shall not have any deformed edges. Pitting below 0.1 mm may be ignored

Read reference books for power plant O&M

For more related articles on power plant

Read

Hi all,

ReplyDeleteFor replacement of a STG, Is there any requirement of Steam Blowing of Outlet MP steam piping, Condensate network and BFW piping of De-super heater.