Understanding the term expansion & contraction

When a body is heated it will expand & when it cooled it contracts. So body

expands & deforms when heated & cooled. Change in temperature of a free

body causes body to expand & contract without inducing stress. When the

deformation of the body is restricted by means of any external force, there

will be huge chances of stress induction. Such induced stresses are called

temperature stresses. These may be tensile or compressive in nature.

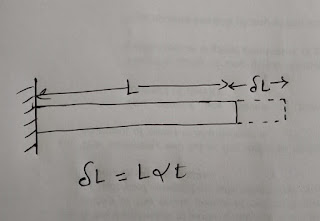

Here L =

Original length of the steel bar

∆t =

Change in metal temperature deg C

ɑ =

Coefficient of thermal expansion

Temperature

strain e = Free deformation / Original length = ∆L / L

E = L ɑ

∆t / L = ɑ ∆t

Temperature

stress σ= Young’s modulus X Strain = E X e

Temperature

stress σ = E ɑ ∆t

Stress

induced in a rigid or constrained body

P =

Force exerted by a rigid support of constraint

We have

σ = P / A

P = E ɑ

∆t A

Expansion in Boilers

Boiler

is made up of plates, tubes, pipes and simple steel of various grades depending

upon the duty conditions. Depending on the service such as cold air/hot

air/cold flue gas/hot flue gas/cold water/hot water/saturated steam/super heated

steam, thermal expansion movement of steel materials takes place to different

extent in Boiler. Ignorance of thermal expansion movement of boiler components

in design/installation may lead to failure of boiler components. The damage to

boiler components can be costly affecting human life in some cases.

There are two types of expansions in Boilers

Absolute

Expansion: Boiler whole mass expands.

Differential Expansion: Individual parts expansion. There are places where there is a

relative expansion movement, which can cause stress in those parts.

In boilers expansion pointers are attached to

all the pressure parts header to under stand the direction & value of

expansion.

Expansion

pointers are used for verifying the expansion movement of the boiler. These are

attached to the drum ends/bottom or top header ends. When the boiler is under

commissioning stage the expansion must be monitored. Depending on the anchor

points in X-axis and Y-axis, the expansion is predicted by designers. The same

is counter checked at site. Deviations in the form of non-uniform expansion

should be checked.

Modern

boilers expand towards bottom, during start ups & shutdown it is very

important to observe the Boiler expansion.

Expansion

of the metals depends on;

- Change

in metal temperature

- Length &

area of the materials

- Coefficient

of expansion of the materials

Provisions for thermal expansions in boilers:

- Boilers all headers bottom space should be free from obstacles

- For air & flue gas ducts expansion bellows may be of

metal or fabric should be provided

- Expansion loops for all steam lines should be provided

- Spring supports & hangers for steam line & hot water

lines

- Rocker washers for steam drum & super heater headers

supports

Precaution to be

taken for free expansion:

- After shutdown, ensure all foreign material from Boilers

& ductings have been removed completely

- Ensure all temporary supports & platforms have been

removed from boilers & ducting

- Ensure there is no welding between any pressure part &

hot ducts with platform or other or beams which can restrict the expansion

- Ensure enough space is available for all bottom headers for

free expansion

- Ensure steam line drains line are free to expand with steam

lines

- Ensure there are no any uneven expansions

Examples:

A square rod of size 20mm X 20 mm in cross section &

2000 mm in length is allowed to expand by fixing both of its ends. Determine

the force developed if the rod is heated from 25 degree c to 150 deg C.

L = 2000 mm

A =20 X 20 = 400 mm2

E = 2 X 105 Mpa

ɑ = 12 X 10-6 0C

∆t = 150-25

= 125 0C

We

have P = σA

P = E ɑ

∆t A

P =2

X 105 X 12 X 10-6 0C X 125 X 400 = 30000 N

Force developed at the end P = 30 KN

What is the expansion of Boiler

side water wall panel , whose total length is 18 meters & metal

temperature is 295 deg c. Consider atmosphere temperature 30 deg c & ɑ = 12 X 10-6 0C

Expansion of side water wall panel ∆L

=L ɑ ∆t = 18 X = 12 X 10-6 X (295-30) =0.068mm = 68mm

Restricted expansion in Boilers or steam lines will lead to..

- Damages to the restricted part

- Damage to the refractory & sealing

|

Available @ Flipcart/Amazon/Notion press

|

Good

ReplyDelete